Frequently Asked Questions

Answers to your frequently asked question. Browse by topic or search for your question.

Or browse the topics below.

FAQs

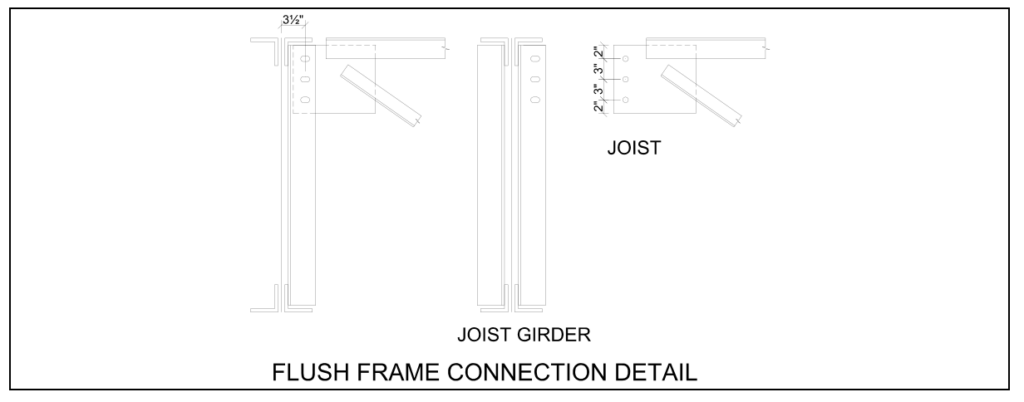

The detail below is a detail for a flush frame joist connection to a joist girder. The dimensions shown are for reference purposes only, however, they can be used for most any flush frame connection.

The plates for the composite joist flush frame connection do not have to be the full height of the WF girder. They should be long enough to accommodate the bolting required for the joist connection and the connection of the joist’s end web angles. It is recommended that the connection have a minimum of three (3) bolts.

Either the shear tab or the joist end plate must have a standard short slot to account for field tolerances. Depending on fabrication techniques the slot can occur in either side of the connection. Remember that punching diameters should not be done on plate thickness thicker than the punch.

There is a higher cost for a flush frame end connection due to the additional material and labor associated with the special end connection compared to the standard bearing seats. They can be used to frame joists or structural steel into with Joist Girders. A small number of flush frame connections will not affect lead times; however, large numbers of these connections will required longer lead times.

Yes. There are increased material, manufacturing, and fabrication costs for the shear tab in the beam and the flush frame plate in the joist. The “standard” bearing seat is not an extra.

Yes. The shear tabs in the wide flange beams for the flush frame joist connections are designed by the project’s Engineer of Record and are shop installed by the steel fabricator.

The design of the bolts and shear tab for the wide flange beam are the responsibility of the project’s EOR. This can be delegated to the steel fabricator provided sufficient information is supplied on the contract drawings for the design. Coordination between the steel fabricator and joist manufacturer detailing departments is key to ensuring smooth and efficient fabrication and construction. There are different ways to do this connection depending on the preference of the steel fabricator and the joist manufacturer. Early coordination is key to success. A minimum of 3 bolts are used. Traditionally bolts are 1”, the joist end plate is 1” and the end plate has short slots which can be punched. If the steel fabricator has the capability ¾” bolts, with a ¾” plate can be used or a combination of 1” material, provided fabrication methods can be done. Slots need to occur in either the shear tab or the end plate, but must be appropriately coordinated.

The joist manufacturer is responsible for the flush frame connection plate that comes with the joist. The connection bolts and the connection components at the wall or to the structural steel are the responsibility of the project’s Engineer of Record.

The flush frame end connection can be used for any joist series or for joist girders. It is however recommended to use LH rather than K-series.

The difference in cost for special connections versus a standard bearing seat will vary slightly between manufacturers and depend on the size (number of bolts) required for the connection.

The three main benefits of using joist bearing seats instead of flush frame connections are: a) lower joist cost for both material and labor, b) lower steel fabrications cost for both material and shop labor, and c) and quicker erection time.